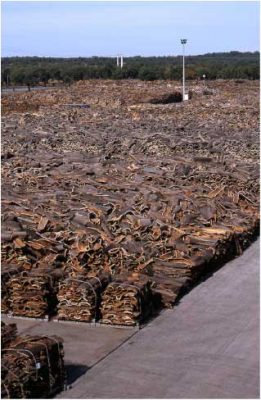

Cork-production

The first step in the development of cork is to maintain a set amount of time and temperature controlled water washing, which ensures that the cork is completely clean. After one hour of cooking, the gas expands in the cork cells. Through this process, the cork forms its honeycombed cellular structure.

At this point of process, the bark will become smooth and flat and the cork volume stretches by approximately 20%. Once this wet process is complete, the flat bark pieces get sorted and cut into respective strips or directly granulated. Thick strips are used to e.g. punch wine corks.